Toggle Navigation

Background:

The traditional ship inspection work requires the ship to be shut down in the harbor for 1 to 2 months for comprehensive equipment dismantling and inspection. The long maintenance time reduces the operating efficiency of the ship, which can simplify the inspection work of the ship and shorten the maintenance window. It has become the best solution to help shipping companies maintain industry competitiveness. HAT is a developer of digital health monitoring systems, providing monitoring and detection solutions for ship rotating machinery status diagnosis and troubleshooting.

Through the cooperation with HAT, Genzo's Rugged Tablet GZ-J110 has carried out timely condition maintenance for 500+ ships.

Challenge:

The marine environment is humid and foggy, and the air is highly corrosive due to salt content. The computer equipment for non-destructive testing operations on board needs to be resistant to salt spray corrosion, waterproof and dustproof, and can withstand the huge temperature difference between indoor and outdoor. difference, especially in the cold winter months, to perform daily tasks flawlessly. In addition, in the face of severe turbulence when the ship is running, the equipment must also be able to withstand severe physical shocks caused by drops and vibrations. These requirements cannot be realized on general computer equipment.

Solution:

Genzo's Rugged Tablet GZ-J110 reinforced plate provides the most cost-effective option for efficient ship inspection work, because it has a completely solid shape, passed the salt spray test, US military Military-810G and IP65 grade waterproof and waterproof Dust certified, with a shoulder strap accessory with an extra layer of operational security, it can be easily used in bumpy sea environments with corrosive electronic equipment. Another key factor in deciding to choose the GZ-J110 device is that it has a high-performance Intel quad-core processor that is perfectly compatible with the HAT digital health monitoring system, and runs the Windows 11 operating system, which can make the detection work more stable.

Advantage:

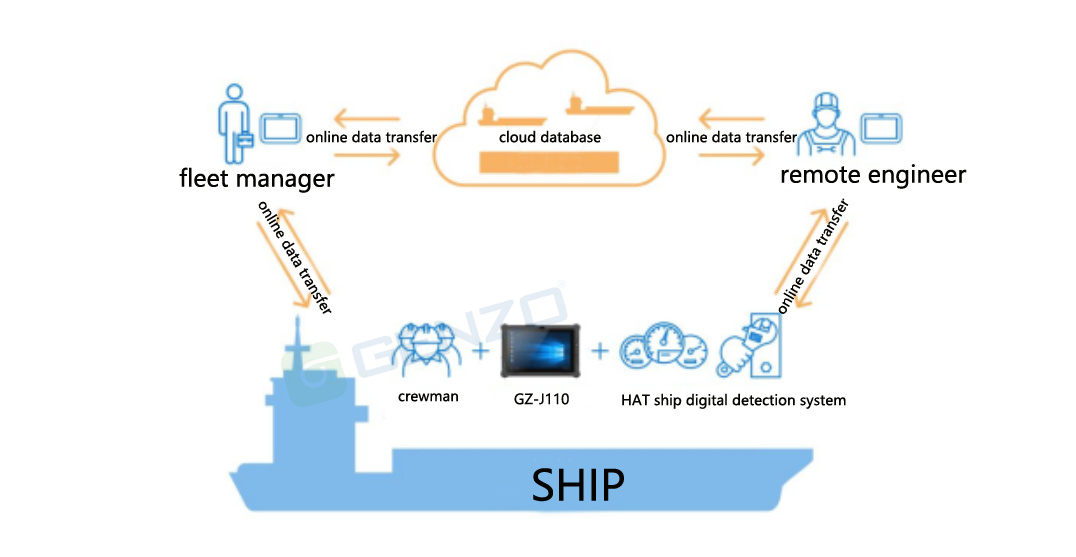

Compared with the previous traditional maintenance methods, the intelligent ship condition monitoring solution brought by the cooperation of GZ-J110 Rugged tablet and HAT digital health monitoring system provides a faster, more effective and more reliable predictive ship machinery maintenance mode. Through portable data collection, instant machinery condition analysis and remote expert diagnosis, unplanned downtime and malfunctioning equipment problems can be warned and repaired in advance, thereby avoiding costly and time-consuming catastrophic failure events.

Challenge:

The normal operation of the ship depends on the availability of the machinery on board, and regular maintenance is necessary to ensure that the ship can always be in good condition. The traditional detection method is mainly to carry out periodic open maintenance on the main equipment carried on the ship based on the running time. The detection process requires dismantling and professional inspection of the ship's equipment. The amount of work is very large and time-consuming. , Ships need to be shut down, and the low maintenance cost intensifies the pressure on ship operation. The predictive maintenance plan can change maintenance from reactive to proactive, prevent potential failures with early problem detection, improve the continuous service life of equipment and shorten the maintenance window period.

HAT is a major provider of predictive maintenance analysis services, and its innovative solutions require the assistance of rugged mobile computing devices that can be used reliably in harsh environments because of offshore operations, extreme temperatures, shocks, vibrations, and salty humidity The air is very common, too fragile equipment will increase the cost of hardware replacement. So which rugged tablet was the right device for them? To find out, HAT conducted an extensive search for data collection tablets that met communications standards and field ruggedness criteria.

Solution:

Genzo's GZ-J110 Rugged tablet is an ideal choice for HAT. As a part of the overall solution, its complete robustness and powerful computing power allow the digital health monitoring system to stably exert real-time monitoring and diagnosis capabilities on the status of ship machinery. In order to realize the early fault detection and timely fault maintenance of the machines on board. The GZ-J110 Rugged tablet which works in cooperation with the HAT digital health monitoring system and metal detectors, can locally convert a large amount of collected vibration detection data into error codes with a small amount of text space, saving the time and movement required for data transmission to the cloud traffic demand. Through the highly interactive and convenient display screen, the test results will be presented directly in front of the crew. The speed at which the crew obtains the measurement results and locates the root cause of the fault is accelerated, and the corresponding maintenance operations can be carried out faster. At the same time, the inspection report of the ship machinery will be automatically generated in just a few seconds and transmitted to the cloud server through the low-latency mobile network of the GZ-J110 Rugged tablet for backup and recording, which is convenient for ship supervisors and fleet managers. Securely access this information and perform data analysis on the cloud from anywhere. In the face of mechanical failures, the crew can take photos of abnormal equipment through the GZ-J110 Rugged tablet HD rear camera and feed them back to the cloud to seek assistance from remote diagnosticians. Thanks to the unique advantages of instant information sharing, professional maintenance Decisions are guaranteed to be communicated the first time.